Construction steps:

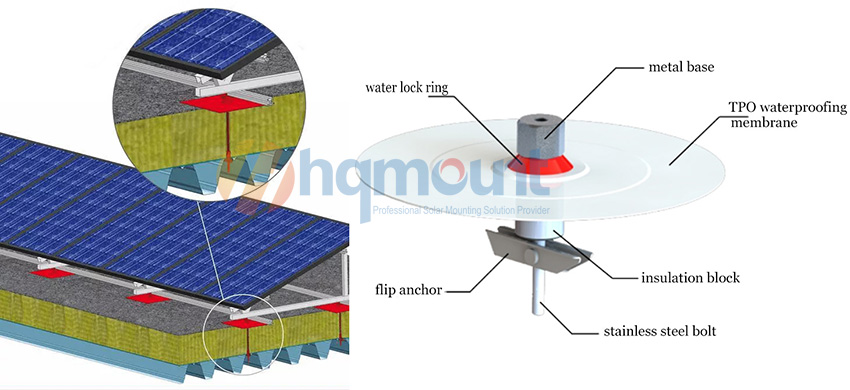

(1) Positioning and drilling: according to the design of the bracket drawing, positioning is carried out, and then specific tools are used to drill;

(2) Clean the hole and clean the table: clean up the rock wool debris in the hole, and use a neutral solution such as ethanol and acetone to clean the area around the hole that needs hot air welding;

(3) Bracket installation: use professional tools to install the metal bracket, and fasten the bracket to ensure that the installation is firm;

(4) Hot air welding: Arrange professionals to conduct on-site hot air welding;

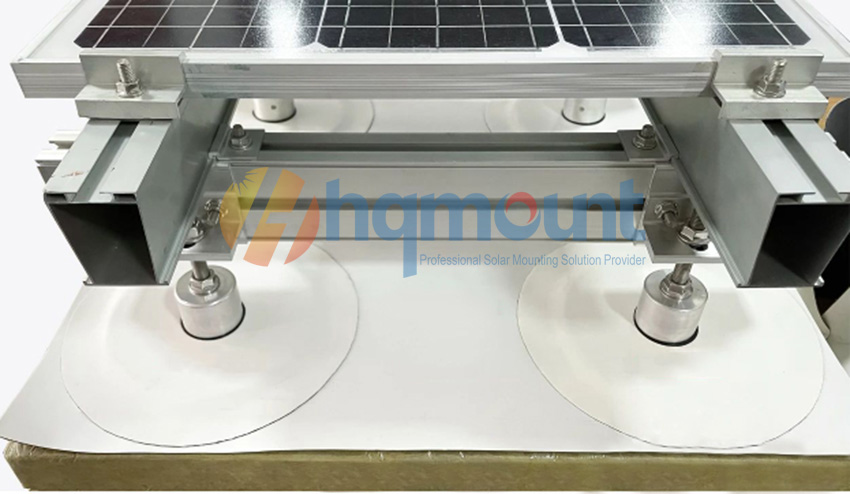

(5) Guide rail installation: Carry out the necessary tests according to the relevant specifications, and install the aluminum alloy main guide rail and auxiliary guide rail;

(6) Component installation and wiring: component installation and wiring.

HQ's photovoltaic mount are easy to install and suitable for various components. HQ will design corresponding safety design solutions for different projects.

HQ MOUNT has been specializing in the manufacture and design of solar mounting systems for over 13 years. HQ products have been installed and used in more than 60 countries and regions, with a total installed capacity of more than 8GW; all projects have been accepted by the official acceptance team after construction is completed, and have now been officially put into production.

In the selection of materials, HQ adheres to the principle of quality first. The bracket is made of high-quality main material, high-grade anodized aluminum AL6500-T5, and the surface is anodized 12-15MIC. Its excellent anti-corrosion and anti-rust properties ensure its 30-year service life; the lightweight nature of aluminum reduces the load on the roof, making it safe and reliable. The maximum wind speed can carry 60m/s, and the snow load capacity can reach 1.4KN/㎡.

Finally, all support solutions at the headquarters are based on the results of field verification. HQ's advanced technical team analyzes the structural form of the building, combines the layout of the photovoltaic matrix and the verification of photovoltaic modules, provides various feasible support arrangements, and determines the most efficient, convenient, safe and reliable solutions.

HQ MOUNT's various efficient and flexible photovoltaic mounting solutions are waiting for you here! Welcome to consult!

86 05926252889

86 05926252889 allie@hqmount.com

allie@hqmount.com