So what is the performance of corrosion with different materials solar mounting systems?

For the corrosion we will cover natural corrosion and the corrosion between 2 different materials in solar PV system.

Here we will include the most commonly used materials for solar bracket.

1, Solar aluminum mounting system

Of all materials, aluminum surely have the best an-ti corrosion performance and the most durable material. In HQ Mount’s decades of supplying mounting structure, we have offered mill surface aluminum structure and anodized solar structure too.

A.Most of solar panel clamps ---Mid clamps and End clamps are made from Aluminum. Because all the Framed solar panels, the frame is made from aluminum and using aluminum solar clamps can avoid electrochemical corrosion.

B.Aluminum surface treatment. This is actually depends on country standard and the atmosphere corrosion. In some countries, mill surface solar profiles are accepted. Which the most common anodizing layer AA10 manufactured by HQ Mount. Also, we have done AA15 in the seaside, and AA15 for the black solar profile.

2.Photovoltaic steel structure

Steel structure PV system used to be hot dip galvanized only which is very commonly used in large scale solar systems. The HDG coating layer are mostly 80㎛ produced by HQ Mount. But some other people will choose 60 ㎛ to cut off the cost.

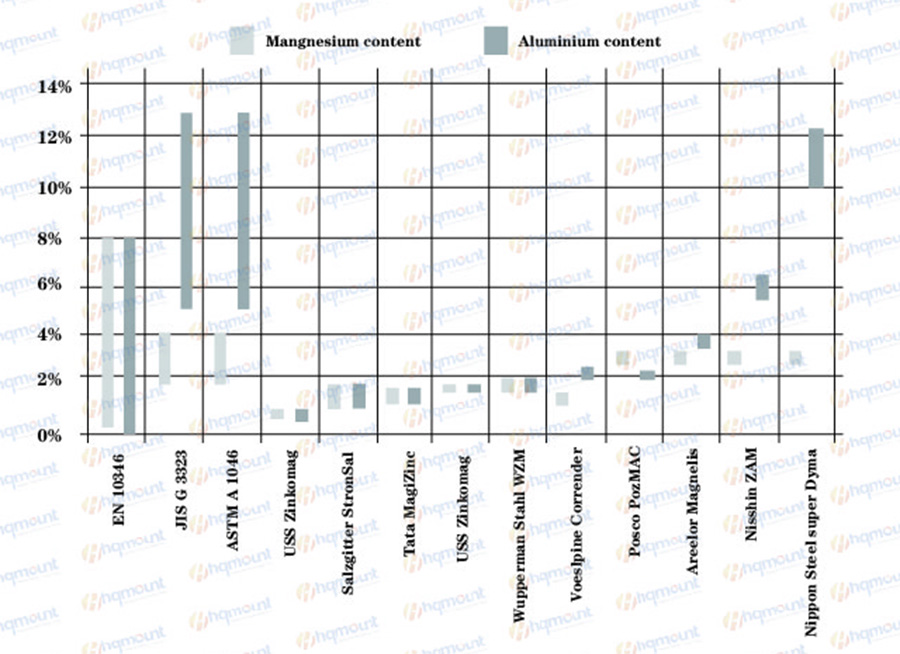

But with the solar technology developed, magnesium zinc aluminum coating are commonly used. The internationally known brands are: Magnelis®from Europe, PosMAC from Korea and others in the following figure1.

FIGURE 1 MAIN SUPPLIER FOR ZAM.

In China, the suppliers are known as:

A, TANG STEEL

B,Beijing Shougang

C, Baosteel

D,Jiu Steel

From the above 4 corp for steel, HQ Mount chose Jiu steel, and buys from Jiu steel thousands of tons every month which makes our solar raw materials cost lower than others. The reason we choose Jiu Steel is because after comparing the aluminum and magnesium contents, Jiu steel’s performance is better for anti- corrosion especially for the long lifetime solar ground mounting systems.

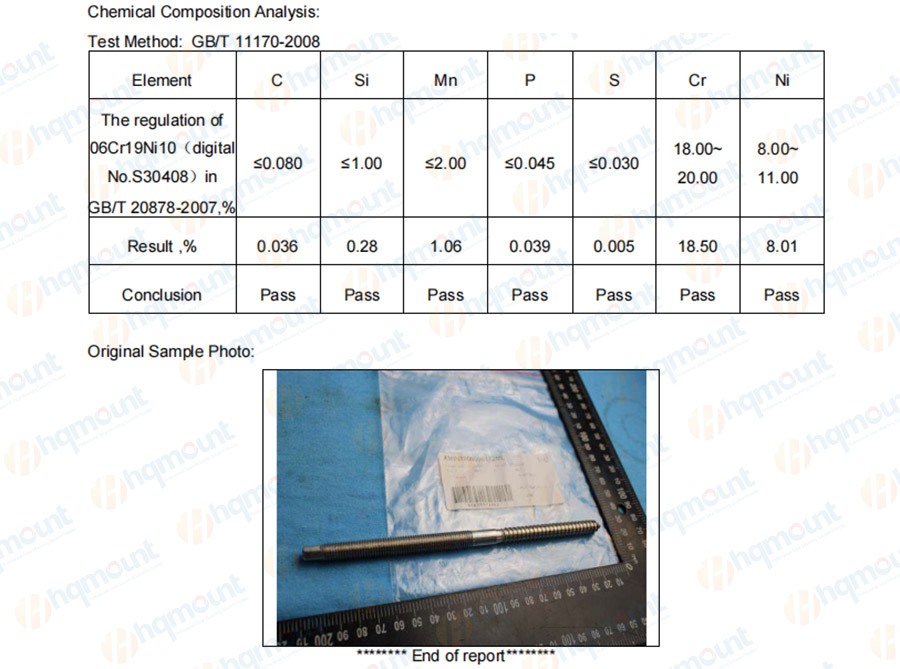

3, Stainless steel solar components.

Stainless steel doesn’t mean that it won’t corrosion. It’s only means the anti-corrosion is better than others. The most important part for stainless steel fasteners performance is based on the nickel percentage.

SS316 higher than SS304 (1.4301) but cost around 20% higher

SS304 more Nickel than SS410, but SS410 hardness is is better so for solar screws SS410 are the most commonly used. SS304 are mostly commonly for solar bolt and nut. But while the solar bracket is using magnesium zinc aluminum alloy to avoid chemical corrosion 8.8 grade solar fastener kit will be used.

SS430 doesn’t included nickel, but since solar hooks are hidden under solar panel and solar tile roofs so it can be used for solar roof hooks as well. Some people will choose SS304 A2 solar hooks considering the corrosion of atmosphere level.

HQ Mount test for different materials:

1, aluminum module clamps by SGS

FIGURE 2. SGS APPROVED PANEL CLAMPS

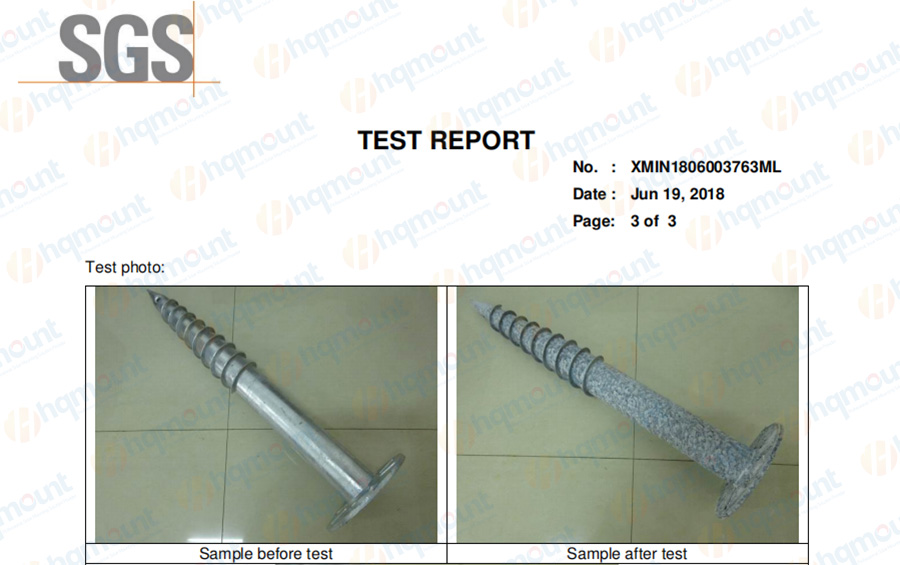

2,Hot dip galvanized solar ground screw testing

FIGURE 3. SGS TESTING SOLAR GROUND ANCHOR

3,Stainless solar hanger bolt SGS testing report

FIGURE 4. SOLAR HANGER BOLT CHEMICAL COMPOSITION TESTING REPORT

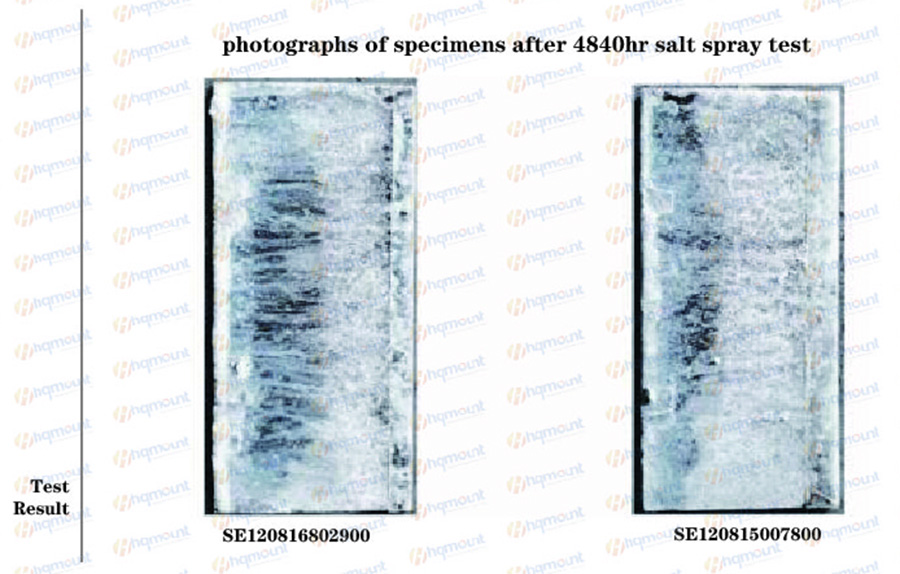

4, Magnesium zinc aluminum alloy testing report.

FIGURE 5. Solar ZAM testing report

Xiamen HQ Mount Tech Co.,LTD---China solar mounting system supplier , we have our own testing equipment for the material performance.

FIGRE 6. Solar bracket anti-corrosion testing machine

Kind reminders:

When you are choosing a solar bracket supplier , the cost of solar modules are much more than solar rack, so if you are choosing lower cost check:

1, Aluminum alloy anodizing layer and report

2, Which supplier is the steel and what’s the coating layer

3, What’s the performance with salt spray?

86 05926252889

86 05926252889 allie@hqmount.com

allie@hqmount.com